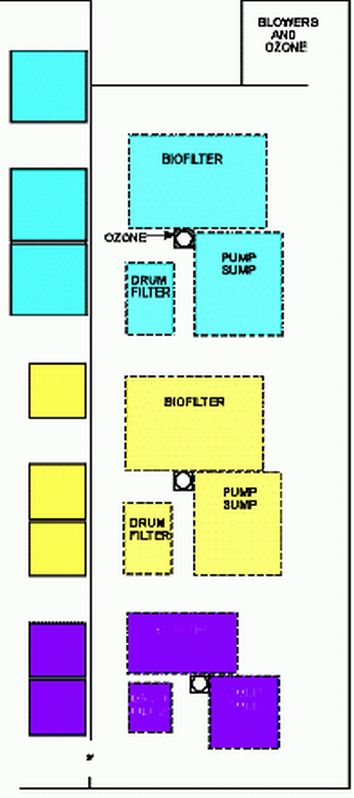

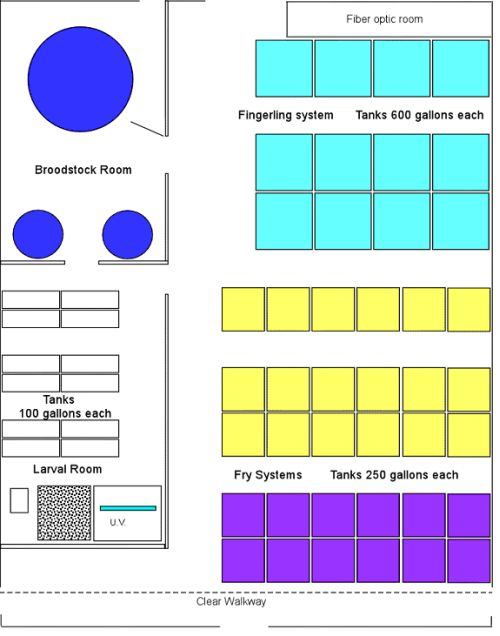

Hatchery Layout. The

separate colors represent individual systems. The larval room has its

filtration components within the room, but other systems have the

filtration components outside of the building.

Sturgeon Larval and Fingerling Production

Egg and Larval Systems

Until

our Siberian sturgeon are old enough to produce eggs, we will purchase eggs

from other countries culturing these species, such as Hungary Germany

Sturgeon Eggs

When the

eggs hatch, the larvae initiate feeding one

week later and are fed at 10% of their body

weight. The

larvae are fed a commercial feed at hatch and will remain in the larval

room system for approximately

6 weeks (0.6 grams in weight).

Larval System

Fingerling Systems

After transfer to the fry and fingerling systems, the fingerlings are fed a commercial feed. The feed is dispensed by automatic feeders hanging above each tank. The fish will stay in the hatchery for 5-8 months before being moved to the growout facility.

The complete building diagram is shown to the left.