Processing

Caviar processing requires extremely sanitary conditions. We are achieving this condition by constructing our processing plant specifically for the production of caviar. Every aspect of the plant complies with the Food and Drug Administration (FDA) Food Code 2001 and Current Good Manufacturing Practices, as well as with the State of

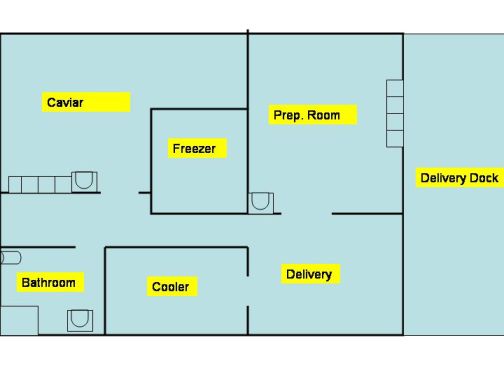

The plant is designed to receive the whole fish, remove the eggs, move and process the caviar in a linear flow. The caviar, which is a Ready-to-Eat Product, will never travel back through an area that is likely or remotely possible to contaminate it. Once, the eggs are cleaned and passed through a screen, they are salted and placed in jars for marketing. These jars will be stored just below freezing to optimize the shelf life. Using these latest technologies, we will be able to produce “Malasol” caviar! That is… caviar that is not as heavily salted. This is achieved through near perfect sanitation and low temperature refrigeration. Also, our on-site facility allows for the least possible time from harvest to processing.

Processing and Harvesting

Once the sturgeon reach a marketable size (approx. 4 kg), the males are harvested for meat. The females are allowed to grow until approximately 5-6 years of age (7-10 kgs) when they will produce caviar. We expect the caviar to comprise approximately 10% of the female fish’s body weight. At the time of harvest, the female fish will be processed in a similar manner as the male sturgeon were; however, the caviar of the females will be further processed for marketing.

Construction of the caviar processing building is currently underway with an expected completion in February 2004. The sturgeon production operation will ultimately sustain a biomass of 200 tons of sturgeon, yielding 75 tons of meat and 4.2 tons of caviar per year when in full operation.

<>